Finger joints, such as the ones used by the web-based box designer at http://boxmaker.rahulbotics.com, depend on accurate dimensions to provide a tight fit. If you take the standard settings, it assumes that the parts are cut out with no loss of material. Since there is always some loss, that creates a box that fits together, but loosely.

To get a tight fit, you need to click on Advanced Options and enter the real kerf width where it says Cut Width.

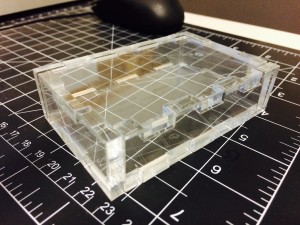

I ran some tests with quarter-inch acrylic (pretty typical for boxes) and found that a Cut Width of 0.005″ is about right for our laser today. That’s right in the middle of what the web page says are typical values. You can probably get away with just using 0.005 for your project. Of course, if you need the best fit, you’ll have to run your own tests on your material on the day you’re cutting it.

You’ll also want to use an accurate setting for Material Thickness. It turns out that quarter-inch acrylic is nominally 0.22″, and half-inch is 0.472″, and both of those numbers vary a bit. For perfect results, use a micrometer on your material.