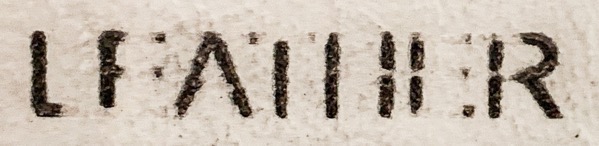

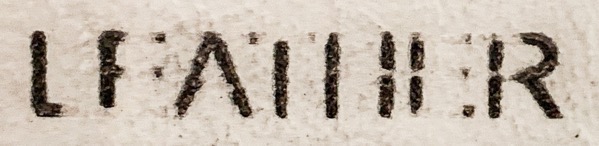

One of the characteristics of our laser is that when raster engraving, vertical edges tend to be emphasized. As the head travels across the image, whenever it encounters a transition from laser-off to laser-on, an extra pulse of power is generated as the laser starts firing. This extra pulse of power adds to the laser’s effect on the material at that edge. Here’s an example, taken from the front cover of the first volume of our log book.

The original image artwork was filled-in black letters, with no outline features. All the outlining you see is due to the extra power pulse effect. (There’s some doubling of the lines because I bumped the notebook slightly before trying a second pass.) The effect is especially noticeable in this case, because we’re engraving on paper with a colored glossy coating, which is very easy to cut and reveals differences in cutting power. If you examine the B in that image, you can see that true horizontal edges are not emphasized, but all the edges that have a vertical component have an extra outline. It doesn’t matter whether the vertical edge is on the left or right side of the filled area, because the laser fires in both directions when rastering.

Full Spectrum Laser told me this was an unavoidable property of CO2 lasers. I have my doubts about that. I suspect that smarter controller electronics could compensate for any such tendency and reduce or eliminate the problem. I’ve seen work from other brands of laser that don’t show this effect. Be that as it may, we are stuck with the problem.

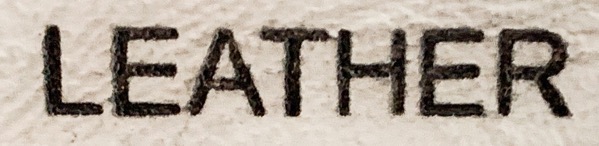

Today I was calibrating laser speed and power on some scraps of light-colored leather I picked up at Artist & Craftsman Supply. For my raster test image, I just used some plain Arial text. Here’s one of my first results.

As you can see, the horizontals are pretty much invisible. The square geometry of Arial text makes the effect very noticeable. (If you look closely you can also see some evidence that the explanation I gave above isn’t the whole story.)

My usual workaround for the problem is to use more power. Most materials change color quickly from their original color to their laser-burned color, and additional power just cuts deeper into the material. If we use enough laser power to fully change the color of non-vertical features, then the vertical features won’t be darker than the other engraved areas. They’ll just be deeper, which is not nearly as obvious to the eye. That workaround won’t work with this leather, any more than it worked with the logbook cover above, because the leather has a thin top layer that we don’t really want to penetrate.

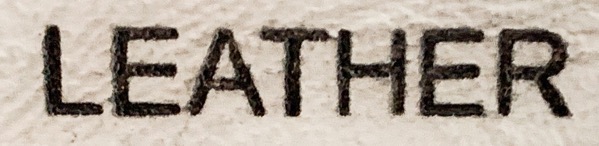

Today’s invention is a new workaround. I rotated the image of the text by 45 degrees in the drawing program, and also rotated the leather 45 degrees on the laser bed. In effect, this rotates the raster scan 45 degrees with respect to the artwork, without otherwise changing the design. Here’s the result.

As you can see, this is like magic on the small Arial text. The dominant horizontal and vertical lines are all rendered rather nicely. As it happens, this sample doesn’t contain any significant edges at a -45 degree angle, so all the edges are emphasized equally. The sample also doesn’t contain any wide areas to be engraved, so effectively it’s all edges. If the text were larger, you’d probably see that each stroke of the letterforms had two strong edges around a weaker middle, but that’s invisible at this scale. It would still be a nicer effect than losing the horizontal lines.

There isn’t anything magic about 45 degrees, except that it theoretically balances the effect between horizontal and vertical edges. You can use whatever rotation you need in order to minimize the visual importance of lines and edges that are parallel to the raster scan. If your artwork was a geometric design with lots of lines at 45 degree angles, you’d definitely want to use some other angle.

This isn’t a complete solution, of course, but it’s a useful trick to know about when it’s applicable.