Progress on laser setup. Friday I got the water chiller connected (with new, longer water hoses and signal cable), which meant I could safely power on the laser and do some tests and initial alignment. So far, so good. Also got the computer hooked up to the laser (with a new, longer Ethernet cable) and the air assist compressor connected. Main things still to set up: the exhaust blower and the air conditioner.

- The first 5 millisecond test pulse from the laser, shown as a dark spot on a thermal printer sticker. This confirms that the tube survived shipment and installation!

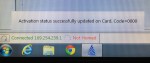

- First launch of the RetinaEngrave3D software with the laser actually connected. It phones home and validates the software license for the controller card.

- Some of the test dots fired during initial alignment. The alignment procedure was completed but the results still need to be confirmed.