I’ve updated the comprehensive Laser Job Checklist to match the new laser configuration and software environment. You can get a PDF copy in the Downloads section on this site.

Author Archives: Sol Diego

February Class Scheduled

Basic laser operation and safety class is scheduled for Tuesday, February 24, at 6:30pm – 10pm.

Please email me class@colaser.org to reserve your place in the class. Because the laser room is small, the class size is limited to 6.

Expect about 90 minutes in the classroom, followed by practical hands-on exercises in the laser room. Once you complete the class, you’ll be able to schedule time on the laser to do your own projects.

Engraving Steel

I’ve been saying that the laser can’t engrave metals, with the possible exception of light engraving on stainless steel. Well, after class this afternoon we decided to try it. Turns out, the laser really can engrave stainless steel, for at least this one (unknown) type of stainless. It cuts a nice little divot out of the steel. The skull logo is about one inch across:

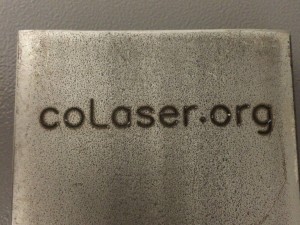

Emboldened by this result, we also tried engraving one of the steel weights. These are standard cold-rolled steel, not stainless. They aren’t rusting because I sprayed them with clear spray paint. The laser successfully marked the surface of the steel, but didn’t penetrate to any significant depth. (Or maybe it just burned the clear spray paint. I didn’t have any unpainted steel handy.) The text is about two inches across.

Both of these were vector jobs cut at 100% current, 100% power, and 10% speed. The speed could be lowered even more to get a deeper cut. Even these big thick chunks of metal were noticeably warm after the job.

On both jobs, you can clearly see the spot where the laser started to cut each vector. There’s less discoloration and a bit more depth in that spot. The rest of the cut is pretty consistent, but somewhat rough. You’d have to test your specific material and decide if you like the effect.